Industrial Chillers 1 – 3kW

Industrial Chillers 1 – 3kW

The S series Chillers are designed to cool processes with small heat loads.

The S series Chillers are designed to cool processes with small heat loads.

They can be installed indoors or outdoors and can be configured to supply chilled water for

- Potable water applications

- Process cooling from an internal buffer tank

- Process cooling to an external buffer tank

Features

The chillers are supplied with – as standard

- An internal 40L buffer tank to protect the compressor from excessive start, close temperature tolerance, reduces thermal spikes and allows for vented design with no need for hydronics kit

- Suitable for indoor or outdoor installation

- Rugged galvanized steel construction

- Components sourced from the industries leading suppliers

- R134a refrigerant for high ambient temperature operation and the lowest GWP of all contemporary refrigerants

- Integrated circulation pump

- Comprehensive 12 months warranty on all parts and labour

- Highly accurate electronic controller

- 316SS plate heat exchanger evaporator

- Comprehensive factory testing before dispatch

Chiller Application

Industrial process chillers are designed to circulate water to a heat producing process via a water pump. The water brings the heat back to the chiller where the compression cycle cools the water before it is returned to the heat process.

Technical Data

Technical Data

| Model | TCM010 | TCM015 | TCM020 | TCM025 | ||

| System type | Chiller | Heat rejection | Air | |||

| Capacity

ASHRAE CONDITIONS |

TR | |||||

| Btu/hr | ||||||

| kW | 1.2 | 1.5 | 2.3 | 3.0 | ||

| EER (kW/TR) | ||||||

| Capacity control | % | 0-100% | ||||

| Refrigerant | Type | R134a | ||||

| Total power input | kW | 1.2 | 1.3 | 1.7 | 1.95 | |

| Total running current | Amps | 7.1 | 7.6 | 9.0 | 10.0 | |

| Power requirements | V/Hz/Ph | 220-240/50/1 | ||||

| COMPRESSOR | Scroll Hermetic | Start method | DOL | |||

| Motor size | CM3 | 15.3 | 18.5 | 26 | 34 | |

| RPM | 1/min | 2900 | ||||

| QTY | 1 | |||||

| Maximum Power input | kW | 0.65 | 0.8 | 1.1 | 1.4 | |

| Total running current | Amps | 4.0 | 4.1 | 5.1 | 6.8 | |

| MCC/ comp | Amps | 4.3 | 4.4 | 5.3 | 7.0 | |

| Locked rotor amps | Amps | 16.2 | 22.1 | 21.5 | 27.7 | |

| Oil charge / comp | L | 0.5 | 0.5 | 0.6 | 0.6 | |

| Oil type | POE | |||||

| CONDENSER | Air cooled – heavy duty – high ambient design | |||||

| Material | Aluminum, blue fin on copper tube | |||||

| Tube diameter | Inch | 7mm | ||||

| Fin spacing | mm | 2.1 | ||||

| CONDENSER FANS | External, axial fans, 4 pole – speed controlled | |||||

| Fan speed | Rpm | 900 | ||||

| Fan diameter | mm | 350 | ||||

| No fans | 1 | |||||

| Total power input | kW | 0.3 | ||||

| Total running current | Amps | 1.4 | ||||

| Total air flow | M3/ hr | 3000 | ||||

| EVAPORATOR | Plate heat exchanger | |||||

| No. refrigeration circuits | 1 | |||||

| Chilled water flow rate | l/s | 0.1 | 0.1 | 0.2 | 0.2 | |

| Pressure drop | kPa | 50 | ||||

| Inlet / outlet CHW Temperature | C | 12/07 | ||||

| Working temp range | C | 05/20 | ||||

| Water connections | mm | ½” push fit | ||||

| Evaporator protection | Flow switch | |||||

| Expansion | Capillary | |||||

| CONTROLLER | Standard electronic – Dixell | |||||

| HP Safety | 2850kPa | LP Safety | 375kPA | |||

| Shipping weight – dry | Kg | 75 | 76 | 76 | ||

| Buffer Tank | Litres | 40 | ||||

| BMS protocols | – | Buffer tank construction | Stainless steel | |||

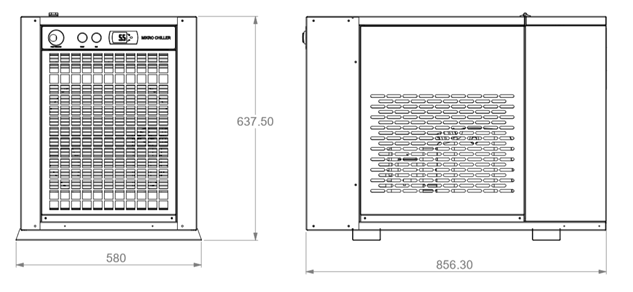

Dimension

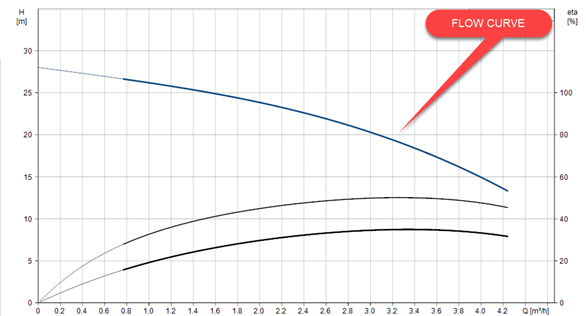

Pump performance

Primary Pump Curve

Pump data

- RPM 2900

- Approvals – CE,WRAS,ACS,TR,EAC

- Housing – cast iron

- Impeller – Stainless steel 304

- Rated power 0..55 kW

- Rated Hz – 50

- Rated voltage 220/ 240

- Rated amps 3.1

- Weight 14kg

Options

| Close tolerance (CT) | The chiller can be manufactured with either a hot gas bypass valve for close temperature tolerance. Standard tolerance achievable is ±0.5C depending on load profile

The valve acts retard evaporator capacity as the chilled water temperature approaches set point. |

| BMS Connectivity | The chiller can be connected to the high or low level BMS

Low level connectivity will be dry contact for – Master run – Master fault High level connectivity is Modbus, SNMP and Bacnet over Ethernet without the need for a gate way |

| Potable water supply

(I) |

The chiller can be manufactured to deliver water for potable water application. A typical installation requires the chiller to be connected to the main water and the pressure from the main is used to supply the process. |

| Remote Condensers

(R) |

The chiller can be manufactured as a split system. The evaporator can be installed indoors in a plant room for example and the condenser installed outdoors. |

| High corrosive environments | If the chiller is to be installed in an environment with corrosive elements present the chiller can be manufactured in such a way to extend the life of the unit

These environments can be – Coastal which high levels of salt spray present – Mining with Sulphur present The units can be constructed with stainless steel cabinets, coil protection or copper lacquer doe example The electrical enclosures are weather proof but if an enclosure is required with a high IP rating this can be offered |

| Castors | The chiller can be supplied on wheels for ease of re-location |

All operational cooling capacity, power consumption and current draw data shown above is based on the chiller operating at the limit of its design and is intended to be an indication only.

Each chiller will be individually designed to customer requirements and a detailed product specification will be supplied at time of order including installation instructions and dimensions. The power consumed by the unit and the current it will draw vary depending on how the chiller is constructed. The chillers performance may also vary slightly from the figures above again based on customer requirements.

THERMEX Solutions product range is subject to change without notice

WARRANTY

- THERMEX Solutions warrants all it products for 12 months from the agreed commissioning date – no later than 30 days from invoicing date.

- The warranty is to the first purchases of the unit

- The warranty covers all parts and labour to rectify the unit

- The warranty is subject to THERMEX Solutions terms and conditions which will be provided at the time of order

- Warranty is subject to Thermex Solutions full terms and conditions

About Thermex Solution

Thermex Solutions is Australia’s largest manufacturer of small capacity specialsied industrial water chillers. The technical team at Thermex have a combined 50 years in the Australian chiller industry – no other company can offer this level of engineering support for our customers critical applications.

Rather than offer imported chillers Thermex has dedicated itself to providing locally specified and manufactured chillers which are supplied with components sourced from the industry’s leading suppliers. With specifying chillers experience counts and no other company has the experience to offer the advice and solutions the market requires.

As the Australian market grows and diversifies, Thermex can offer expert advice on chillers, heat pumps, variable speed high efficiency scroll chillers, air handling and more.

Thermex is back by a nationwide team of service technicians who are trained in the operation and maintenance of Thermex chillers

Related products

COMMERCIAL CHILLERS

COMMERCIAL CHILLERS

COMMERCIAL CHILLERS

COMMERCIAL CHILLERS

COMMERCIAL CHILLERS

COMMERCIAL CHILLERS